Feekercn Dual-Wing Expandable Container White House | Foundation-Reinforced, 2-Bed 1-Bath, Energy-Compatible Flat Pack Assembly, Complex Terrain Adaptation

Color

White Panels & Steel Structure & Glass Door/Windows

Product Dimensions

228"L x 240"W x 98"H

Floor Area

380 Square Feet

Layout Inside the tiny home

2 Bedrooms, 1 Bathroom, 1 Living room, 1 Kitchen

Specification of Feekercn Expandable white house

·Layout Inside the tiny home: 2 Bedrooms, 1 Bathroom, 1 Kitchen, 1 Living room

·Main Usage: Tiny Home to live in for adults, or suitable for tiny store, cafe, homestay, etc.

·House Area: 380 sqft

·External Dimensions: L19 x W20 x H8.3 ft

·Folded Dimensions: L19 x W7.3 x H8.3 ft

·Weight: 6000 lb

1.Cement Pedestal Stabilization

Equipped with precast cement pedestals (per grounding structure images), withstanding 12-level winds, suited for slopes/soft grounds. Breaks the grounding stability bottleneck of traditional container homes, supporting wilderness camps or mountain getaways.

2.Dual Energy Compatibility

Reserves gas cylinder ports + power connections (per side-wall pipeline images), enabling off-grid gas cooking and grid-connected power supply. Solves energy adaptation pain points in remote areas, building a full-energy-compatible system for container homes.

3.Flat Pack Extreme Efficiency

Following the 4-step assembly diagram, 4 workers finish in 10 mins. Packed as sea-shipping container-grade modules (per lifting images), overseas mountain camps require no on-site debugging, achieving time and logistics breakthroughs for emergency construction.

4.2-Bed 1-Bath Space Optimization

Symmetric 2-bed layout (per floor plan) ensures privacy, an open living room connects to the kitchen, and the bath integrates an explosion-proof shower + storage cabinet(per bath structure). Solves small-space function adaptation issues via “space optimization”.

5.Full-Cycle Terrain Compatibility

Cement pedestals suit permafrost foundations (anti-frost-heave design), dual-wing structures use weathering steel frames (5000-hour anti-corrosion test). Paired with Flat Pack’s mobility, building a full-cycle terrain-compatible ecosystem for container homes.

features

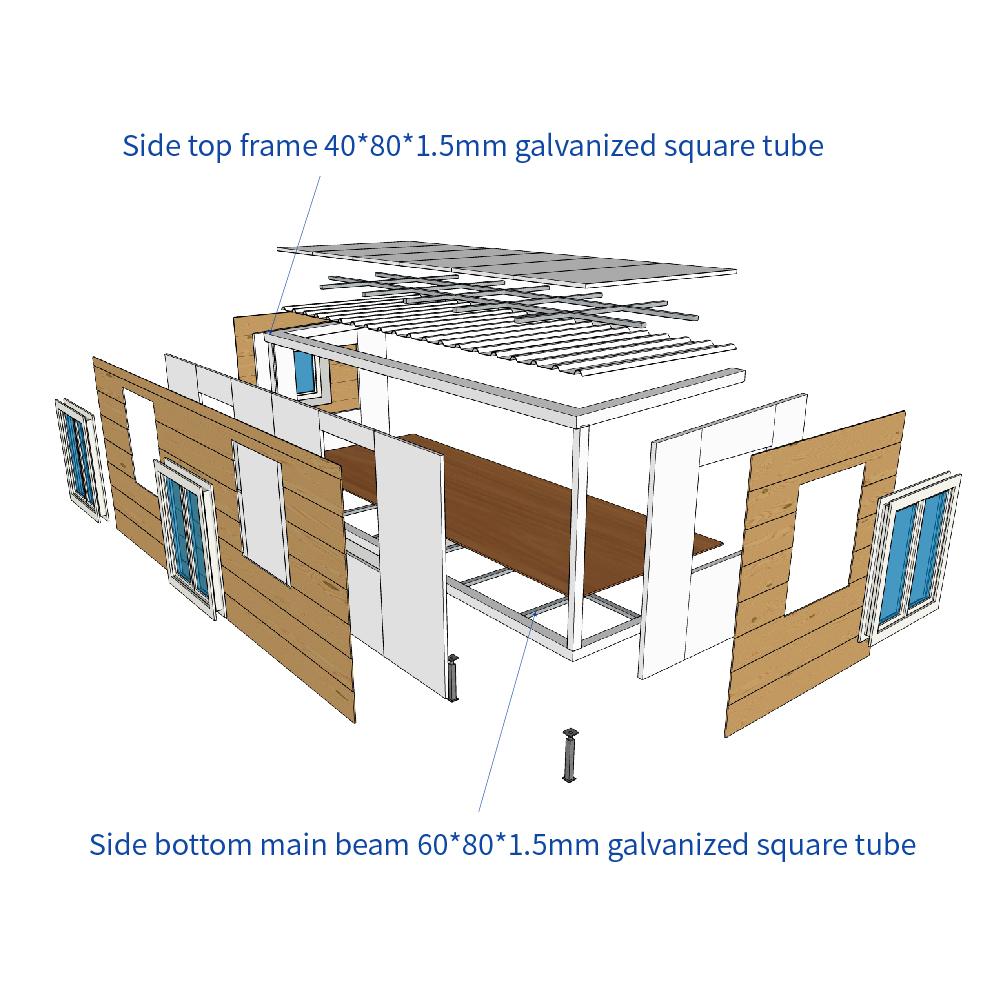

Frame Construction & Wall Panels & Roofs

The Prefab House frame construction is grey, made of thick galvanized steel square tube. Exterior and interior wall panels are made of white galvanized steel sheets, with a 75cm thickness of flame-retardant foam board in between.

Spacious Doors

Included 1 glass entrance door, 1 bathroom door, and bedroom doors as customized requirement. All doors come with standard factory configurations, all equipped with locks.

Security & Bright Windows

9 windows in total (including small 1 for bathroom), all made of aluminum alloy, in white external suspended style with built-in security bars, mosquito screens and locks.

Luxury Flooring

Made with 18mm thick cement-fiber boards, topped with 2mm thick PVC material flooring in a light wood grain pattern.

Full Set Bathroom

we provide a pre installed comprehensive dry-wet separated bathroom. The dry area comprises a toilet, adjustable hot and cold water faucet, a sink and a wall-mounted mirror.The shower area is independent and prefabricated with a showerhead and other standard accessories included

L Shaped Cabinet Set

Includes a set of white L-shaped cabinets with a white high quality sintered stone material countertop, an adjustable hot and cold water faucet, and a sink. Because of the enough space on cabinets surface, you can place some general cooking tools,microwave oven,etc.

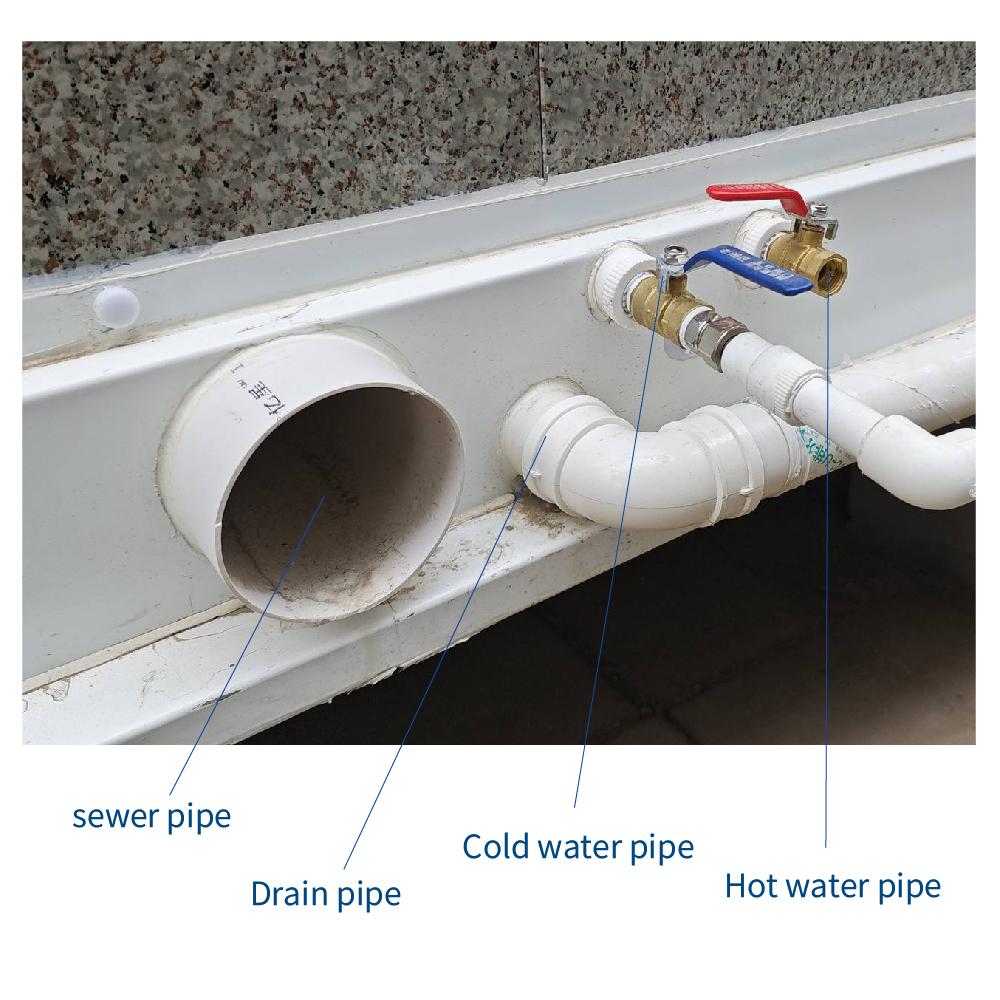

External Water Pipe Connection

The external water pipe connections are installed ready. Included sewer pipe, drain pipe, cold water pipe and hot water pipe connections. So you need to complete the connections with your prepared main water source and sewage tank.

Electrical Configuration

The electrical setup complies with US standards and includes required distribution box, lights, switches, sockets and air conditioning sockets, with all sockets mounted at a height of 450mm from the floor.

notice info

Transportation Process

After you complete the payment and after the house prefabricated, as a special oversized item, this container home will be shipped from our factory to the nearest port via sea freight. From there, the fold out house will be delivered to your specified location via truck. Before the truck arrangement, We will contact you to schedule the delivery time for a smooth receipt.

Receiving Attention

Before purchase, you need to plan the location for receiving the mobile house, ensuring there is enough space and a flat hardened surface to unloading this prefab home. Based on the information of our container house folded dimension L20 x W7.3 x H8.3 ft and weight 6000 lb. You also need to arrange for appropriate unloading machinery, such as a crane, in preparation for the scheduled delivery time.

Installation Attention

This manufactured home does not come with on-site installation workers; you will need to arrange for 3-4 people to assist with the setup. The fold up house features Hydraulic brace on both side panels, and the package includes installation tools such as Hinge pulley block and Wire rope for assembly. Please refer to the instruction and installation videos for guidance.

Customer Service

Regardless of any issues you may encounter when purchasing our container house, such as product-related concerns, transportation, delivery, installation, etc., please do not hesitate to contact our professional customer service team. We are committed to assisting you in resolving any problems you may face.